Tips to Protect Your Water Tank from Corrosion

Water storage in homes is one of the most critical issues today. Mainly because we need this resource to survive and carry out our daily activities; however, we must ensure that the water we use is of good quality and that its supply is sufficient for all family members.

The storage tank is a structure with two functions: to store a sufficient quantity of water to satisfy the consumption demand and to regulate the adequate pressure in the distribution system, thus providing an efficient service. It’s design and construction are varied and depend on the terrain conditions, the material available in the area, the existing labor force, etc.

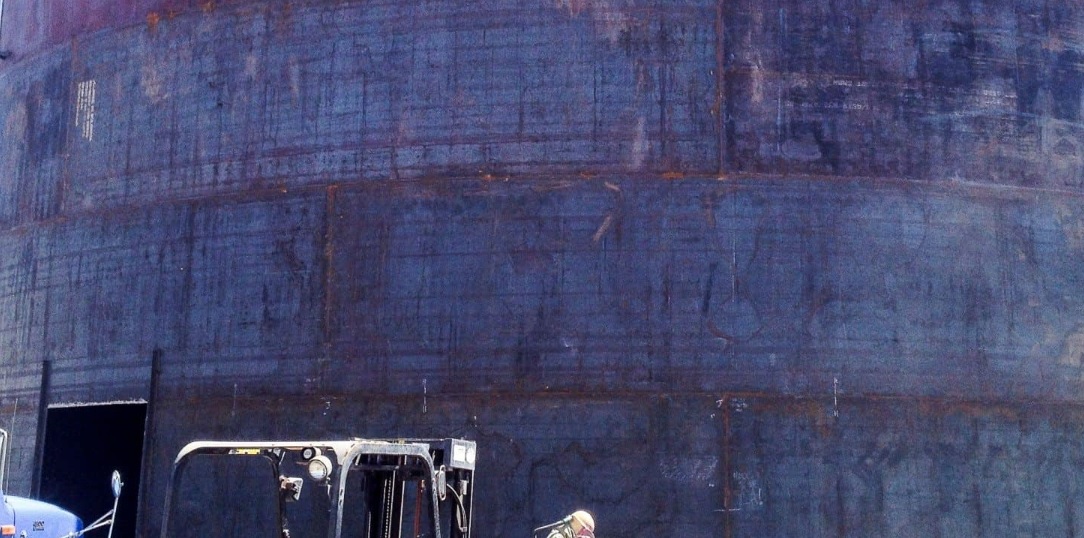

Although steel and fiberglass are often used for smaller water tanks, the larger and more durable tanks and reservoirs are constructed of concrete or asphalt, usually located outdoors, with thousands of gallons inside, requiring special coatings. In addition, because of their continuous use and the environments they must withstand, these structures can develop cracks, which endanger operations and installations.

To ensure and extend the useful life of these storage tanks, tank coating contractors suggest using exterior and interior coatings; otherwise, in case of any failure, the tank would have to be rebuilt, which implies a much higher cost.

The best solutions for coating water tanks and reservoirs depend on two main factors:

- The type of water, whether it is potable or treated.

- The part of the tank to be coated, that is, if it is the interior or exterior.

Now, follow these steps to paint the inside of a potable water storage tank:

Prepare the surface

Pass the abrasive jet over the entire surface to generate roughness and guarantee the adherence of the product. Then, verify that no residue or dirt remains.

Prepare the paint

Mix components A and B of the epoxy paint with its catalyst in a 3:1 ratio by volume (3 parts of component A to 1 part of component B). For this step, you can use mechanical or manual agitation until the mixture is uniform. Then, let it stand for 10 minutes before applying.

Apply three coats of paint

For the first coat, add 25% Thinner to the mixture and stir well. Next, outline the area with a brush and paint one coat over the entire surface using an epoxy paint roller. You can also use a paint spray gun to facilitate the process. When finished, allow the piece to dry for 6 hours.

When applying the second coat, paint with the initial mixture rested and undiluted. You can also use a spray gun or an epoxy paint roller. As with the first coat, let the piece dry for 6 hours.

Paint the third and final coat using the same procedure as above. This time, let it dry for at least 72 hours. Ideally, leave the tank open for eight days for the solvent to evaporate.

Wash the tank before use

Finally, use plenty of water to clean the inside of the tank before using it.

Would you please make sure you choose a product with UV protection? Its chemical composition does not alter the properties of the drinking water; remember, you will drink it; you don’t want to take weird chemicals into your body.

If you are not sure if you can carry out this whole process correctly, the best thing is to look for tank coating contractors.

Comments are closed.